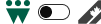

Cunard Street: Live / Work / Grow Building

The new home for FBM is constructed on a 50 ft by 100 ft brown field site in the north end of Halifax; close to the city’s Commons. A one-storey transmission shop was previously located on the site, making the soil and bedrock remediation necessary to allow for the current development. Site plan The Commons, in the centre of the city, forms a green swath of space for recreation, sports fields, and well-being. Surrounding the site is a mix of occupancies, including social housing for seniors, small scale businesses, day cares, bars and restaurants, military uses at the Halifax Armory for the Princess Louise Fusiliers and Cadet units, Urban agriculture, and several architecture firms that have recently chosen this area for their new offices. The design of the new Cunard St Live/ Work/ Grow building embodies the values of FBM Architecture – a place for ‘people driven design’. This is expressed through the firm’s interest in contributing to the community, through the materials, and the work culture that the building supports.

Canadian Wood Council Applauds Strategic Federal Investments in B.C.’s Forest Industry

OTTAWA, March 25, 2025 – The Canadian Wood Council welcomes the Government of Canada’s announcement of over $20 million in funding for 67 projects that support the growth and resilience of British Columbia’s forest sector. While the announcement includes several strategic large-scale investments in advanced wood manufacturing, a significant strength of this initiative lies in the breadth of smaller-scale, high-impact projects that are collectively transforming communities across the province. From feasibility studies for Indigenous-led forest product businesses to the development of next-generation building technologies, these projects are advancing wood innovation, supporting workforce development, and expanding the role of wood in low-carbon construction. Administered through Natural Resources Canada, this Green Construction through Wood (GCWood) funding supports a wide range of initiatives—from fire-testing mass timber connections and refining modelling guides for timber structures, to developing bioenergy solutions and value-added wood processing in Indigenous communities. This announcement underscores the importance of decentralized innovation, where targeted investments in communities and research institutions alike contribute to a stronger, more sustainable forest sector. The Canadian Wood Council applauds this commitment and looks forward to continuing its work with design professionals, governments, and industry partners to support the expanded use of wood in the province through its market-leading WoodWorks program. View the announcement from Natural Resources Canada here:https://www.canada.ca/en/natural-resources-canada/news/2025/03/canada-announces-support-for-british-columbias-forest-sector.html https://www.canada.ca/en/natural-resources-canada/news/2025/03/canada-announces-support-for-british-columbias-forest-sector.html

Canadian Wood Council Applauds Federal-Provincial Investment in Advanced Wood Construction in Quebec

OTTAWA, March 24, 2025 – The Canadian Wood Council (CWC) applauds the joint investment of over $8.5 million by Natural Resources Canada and Quebec’s Ministry of Natural Resources and Forests in four innovative wood construction-related projects across Quebec. These strategic initiatives will help strengthen the manufacturing sector and accelerate the adoption of low-carbon, Canadian-made wood products and technologies in residential construction and other critical community infrastructure. By supporting advanced wood construction methods—including modular mass timber housing, artificial intelligence to modernize engineered wood manufacturing, and the design of tall wood residential buildings—this investment reinforces the essential role of wood in delivering high-performance, low-carbon construction solutions. From a 20-unit modular development and a 21-storey design study to the cultural leadership of the Cree First Nation of Waswanipi in forest-to-form construction, these projects demonstrate how innovative wood technologies can meet urgent housing needs in a sustainable way, through scalable and repeatable, locally driven approaches. The Canadian Wood Council commends both levels of government for recognizing the critical role of Canada’s forest sector in delivering smart, climate-friendly building systems. These investments demonstrate how advanced wood technologies can contribute to addressing urgent housing needs while helping to lower the carbon footprint of the built environment. Design and construction professionals in Quebec can access free technical support related to wood design and construction through the market-leading resource program, Cecobois. The CWC is pleased to provide support further expand the use of wood in residential, commercial, and institutional buildings throughout the rest of Canada through its WoodWorks program. View the announcement from Natural Resources Canada here:https://www.canada.ca/en/natural-resources-canada/news/2025/03/canada-and-quebec-invest-in-sustainable-wood-construction.html

Canadian Wood Council Applauds Federal Investment in Nova Scotia’s Mass Timber Industry

OTTAWA, ON, 21 MAR 2025 – The Canadian Wood Council (CWC) applauds the Government of Canada’s strategic investment in Nova Scotia’s mass timber sector, recognizing its role in advancing low-carbon construction, economic growth, and job creation. This funding will accelerate the fabrication of high-value mass timber components from undervalued eastern spruce, unlocking new opportunities for Canada’s forest sector and expanding the use of advanced wood materials in construction. By supporting the production of Cross-Laminated Timber (CLT) and Glulam in Nova Scotia, this investment strengthens supply chains, creates skilled jobs in the region, and enhances the competitiveness of low-carbon building solutions across Canada. Mass timber is increasingly recognized as a proven strategy for the rapid construction of much-needed housing and other critical infrastructure. Its benefits extend across multi-residential and commercial buildings, offering a scalable, efficient, and sustainable approach to modern construction. Canada’s forest sector is well-positioned to meet the growing domestic demand for sustainable construction materials. This investment will drive innovation in mass timber manufacturing, creating economic opportunities in Nova Scotia while enhancing Canada’s capacity to produce and supply mass timber products nationwide. Expanding domestic production advances low-carbon building solutions and strengthens Canada’s wood manufacturing sector. The CWC applauds this commitment to fostering a resilient and competitive mass timber industry in Atlantic Canada. Through our WoodWorks technical program, we look forward to supporting construction professionals with the knowledge and resources they need to integrate mass timber into more projects across the country. View the announcement from Natural Resources Canada here: https://www.canada.ca/en/natural-resources-canada/news/2025/03/canada-invests-in-nova-scotias-local-mass-timber-industry.html

Reassessment of Reference Design Values for Hem-Fir (N) Dimension Lumber (U.S. Market)

Reassessment of Design Values for Hem-Fir (N) Dimension Lumber (Canadian Market)

Lateral Bracing Requirements – Part 9 of the BC Building Code 2024

Purpose:This publication provides detailed guidance on the BC Building Code 2024 requirements for lateral bracing in Part 9 wood-frame houses. It explains the building material requirements and construction methods necessary to ensure houses are safe and resilient against seismic and wind loads. Impact:This illustrated guide aims to help designers and builders in British Columbia understand and implement the updated Code requirements for lateral bracing. By doing so, it enhances the structural integrity of houses, ensuring they are better protected against environmental hazards, especially earthquakes. Partners:Canadian Wood Council, National Research Council, The Province of B.C., University of Ottawa

Webinar: Efficient Tall Wall Framing using Engineered Wood Products

Webinar: Diversify Your Structural Portfolio: Wood in Low-Rise Commercial Construction

Calgary – Innovations and Challenges in Mid-Rise Construction Workshop

Edmonton – Innovations and Challenges in Mid-Rise Construction Workshop

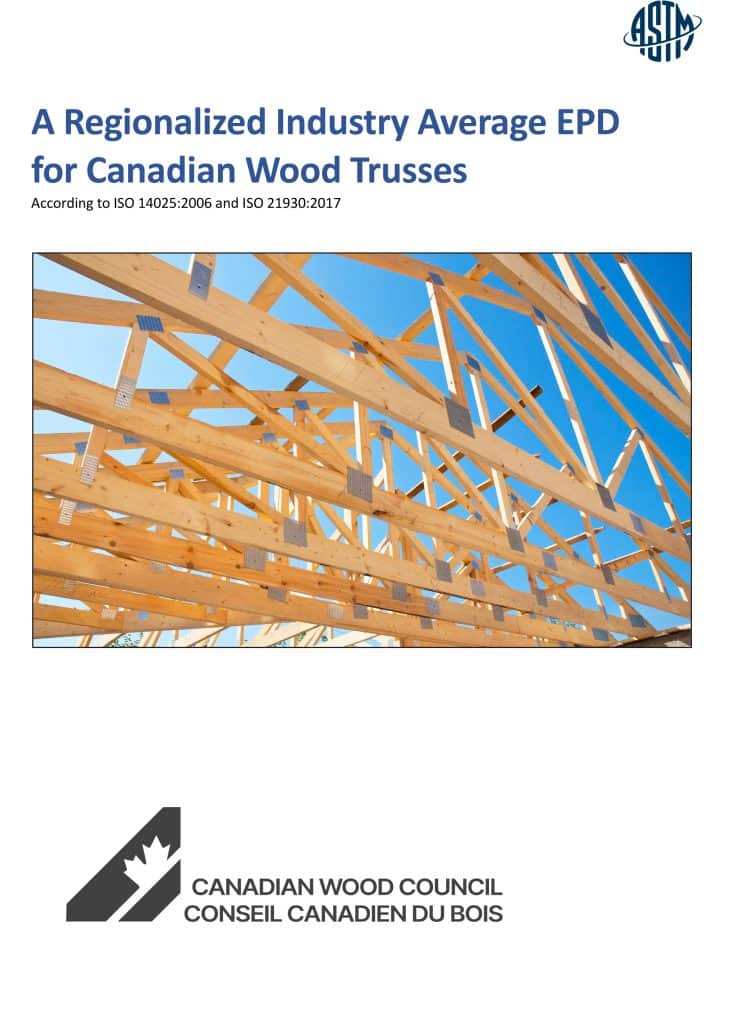

A Regionalized Industry Average EPD for Canadian Wood Trusses