Wood Design & Building Magazine, vol 23, issue 94

National Model Codes in Canada

On behalf of the Canadian Commission on Building and Fire Codes (CCBFC) the National Research Council (NRC) Codes Canada publishes national model codes documents that set out minimum requirements relating to their scope and objectives. These include the National Building Code (NBC), the National Fire Code (NFC), the National Energy Code for Buildings (NECB), the National Plumbing Code (NPC) and other documents. The Canadian Standards Association (CSA) publishes other model codes that address electrical, gas and elevator systems. The NBC is the model building code in Canada that forms the basis of most building design in the country. The NBC is a highly regarded model building code because it is a consensus-based process for producing a model set of requirements which provide for the health and safety of the public in buildings. Its origins are deeply entrenched within Canadian history and culture and a need to house the growing population of Canada safely and economically. Historical events have shaped many of the health and safety requirements of the NBC. Model codes such as the NBC and NECB have no force in law until they are adopted by a government authority having jurisdiction. In Canada, that responsibility resides within the provinces, territories and in some cases, municipalities. Most regions choose to adopt the NBC, or adapt their own version derived from the NBC to suit regional needs. The model codes in Canada are developed by experts, for experts, through a collaborative and consensus-based process that includes input from all segments of the building community. The Canadian model codes build on the best expertise from across Canada and around the world to provide effective building and safety regulations that are harmonized across Canada. The Codes Canada publications are developed by the Canadian Commission on Building and Fire Codes (CCBFC). The CCBFC oversees the work of a number of technical standing committees. Representing all major facets of the construction industry, commission members include building and fire officials, architects, engineers, contractors and building owners, as well as members of the public. Canadian Wood Council representatives hold membership status on several of the standing committees and task groups acting under the CCBFC and participate actively in the technical updates and revisions related to aspects of the Canadian model codes that apply to wood building products and systems. During any five-year code-revision cycle, there are many opportunities for the Canadian public to contribute to the process. At least twice during the five-year cycle, proposed changes to the Code are published and the public is invited to comment. This procedure is crucial as it allows input from all those concerned and broadens the scope of expertise of the Committees. Thousands of comments are received and examined by the Committees during each cycle. A proposed change may be approved as written, modified and resubmitted for public review at a later date, or rejected entirely.

Wood design in the National Building Code of Canada

The current edition of the National Building Code of Canada (NBC) is published in an objective-based format intended to allow more flexibility when evaluating non-traditional or alternative solutions. The objective-based format currently in use provides additional information that helps proponents and regulators determine what minimum performance level must be achieved to facilitate evaluation of new alternatives. Although the NBC helps users understand the intent of the requirements, it is understood that proponents and regulators will still have a challenge in terms of demonstrating compliance. In any case, objective-based codes are expected to foster a spirit of innovation and create new opportunities for Canadian manufacturers. Requirements related to the specification of structural wood products and wood building systems that relates to health, safety, accessibility and the protection of buildings from fire or structural damage is set forth in the NBC. The NBC applies mainly to new construction, but also aspects of demolition, relocation, renovation and change of building use. The current NBC was published in 2015, and is usually updated on a five-year cycle. The next update is expected in 2020. In terms of structural design, the NBC specifies loads, while material resistance is referenced through the use of material standards. In the case of engineering design in wood, CSA O86 provides the designer with the means of calculating the resistance values of structural wood products to resist gravity and lateral loads. Additional design information is found in the companion documents to the NBC; Structural Commentaries (User’s Guide – NBC 2015: Part 4 of Division B) and the Illustrated User’s Guide – NBC 2015: Part 9 of Division B, Housing and Small Buildings. In Canada, structural wood products are specified prescriptively or through engineered design, depending on the application and occupancy. Design professionals, such as architects and engineers, are generally required for structures that exceed three-storeys in height or are greater than 600 m2 or if occupancies are not covered by Part 9 ‘Housing and Small Buildings’ of the NBC. Housing and small buildings can be built without a full structural design using prescriptive requirements found in Part 9 of the Code. Some Part 9 requirements are based on calculations, others are based on construction practices that have a proven performance history. Generally prescriptive use is allowed if the following conditions are met: three-stories or less 600m2 or less uses repetitive wood members spaced within 600 mm spans are less than 12.2 meters floor live loads do not exceed 2.4 kPa residential, office, mercantile or medium-to low-hazard industrial occupancy The rationale for not basing all Part 9 requirements on calculations comes from the fact that there has been historical performance and experience with small wood-frame buildings in Canada, in addition to the notion that many of the non-structural elements actually contribute to the structural performance of a wood-frame system. Quantifying the ‘system’ effects on overall behaviour of a wood-frame building cannot be done adequately using typical design assumptions, such as two-dimensional load paths and single member engineering mechanics. In these instances, the requirements for houses and small buildings is based on alternative criteria of a prescriptive nature. These prescriptive criteria are based on an extensive performance history of wood-frame housing and small buildings that meet current day code objectives and requirements. Buildings that fall outside of prescriptive boundaries or are intended for major occupancy or post disaster situations must be designed by design professionals in accordance with Part 4 of the NBC. Structural resistance of wood products and building systems are engineered according to the requirements of CSA O86 in order to resist the loadings described in Part 4 of the NBC.

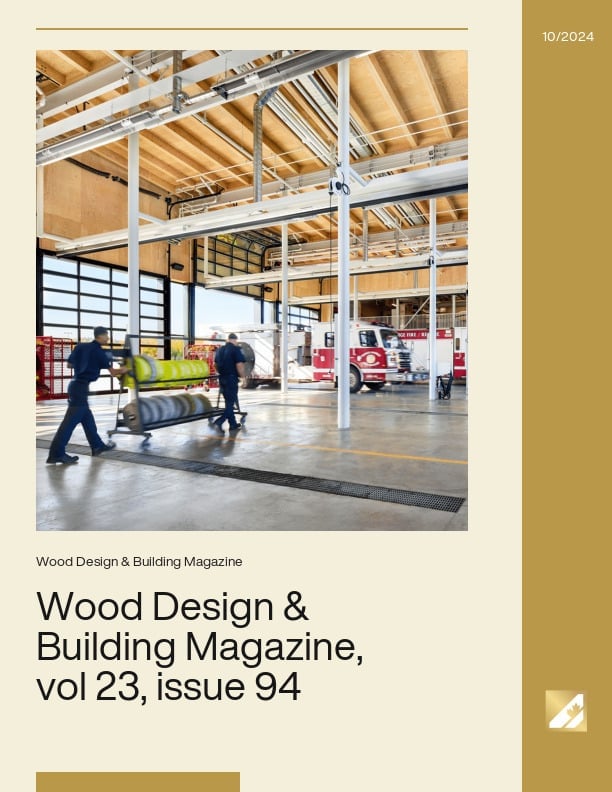

Mid-Rise Buildings

In the early 1900s, light-frame wood construction and heavy timber, up to ten-storeys in height, was commonplace in major cities throughout Canada. The longevity and continued appeal of these buildings types is apparent in the fact that many of them are still in use today. Over the past decade, there has been a revival in the use of wood for taller buildings in Canada, including mid-rise light-frame wood construction up to six-storeys in height. Mid-rise light-frame wood construction is more than basic 2×4 framing and wood sheathing panels. Advances in wood science and building technology have resulted in stronger, safer, more sophisticated engineered building products and systems that are expanding the options for wood construction, and providing more choices for builders and designers. Modern mid-rise light-frame wood construction in incorporates well researched and safe solutions. The engineering design and technology that has been developed and brought to market is positioning Canada as a leader in the mid-rise wood-frame construction industry. In 2009, via its provincial building codes, British Columbia became the first province in Canada to allow mid-rise buildings to be made from wood. Since this change to the British Columbia Building Code (BCBC), which increased the permissible height for wood frame residential buildings from four- to six-storeys, more than 300 of these structures have been completed or are underway with BC. In 2013 and 2015, Québec, Ontario, and Alberta, respectively, also moved to permit mid-rise wood-frame construction up to six-storeys in height. These regulatory changes indicate that there is clear market confidence in this type of construction. Scientific evidence and independent research has shown that mid-rise wood-frame buildings can meet performance requirements in regard to structural integrity, fire safety, and life safety. That evidence has now also contributed to the addition of new prescriptive provisions for wood construction, as well as paved the way for future changes that will include more permissible uses and ultimately greater permissible heights for wood buildings. As a result of this research, and the successful implementation of many mid-rise wood-frame residential buildings, primarily in British Columbia and Ontario, the Canadian Commission on Building and Fire Codes (CCBFC) approved similar changes to the National Model Construction Codes. The 2015 edition of the National Building Code of Canada (NBC) permits the construction of six-storey residential, business, and personal services buildings using traditional combustible construction materials. The NBC changes recognize the advancements in wood products and building systems, as well as in fire detection, suppression, and containment systems. In relation to mid-rise wood-frame buildings, several changes to the 2015 NBC are designed to further reduce the risks posed by fire, including: increased use of automatic sprinklers in concealed areas in residential buildings; increased use of sprinklers on balconies; greater water supply for firefighting purposes; and 90 percent noncombustible or limited-combustible exterior cladding on all storeys. Most mid-rise wood-frame buildings are located in the core of smaller municipalities and in the inner suburbs of larger ones, offering economic and sustainability advantages. Mid-rise wood-frame construction supports the goals of many municipalities; densification, affordable housing to accommodate a growing population, sustainability in the built environment and resilient communities. Many of these buildings have employed light-frame wood construction from the ground up, with a five- or six-storey wood-frame structure being constructed on a concrete slab-on-grade, or on top of a concrete basement parking garage; others have been constructed above one- or two-storeys of noncombustible commercial occupancy. Mid-rise wood buildings are inherently more complex and involve the adaptation of structural and architectural details that address considerations related to structural, acoustic, thermal and fire performance design criteria. Several key aspects of design and construction that become more critical in this new generation of mid-rise wood buildings include: increased potential for cumulative shrinkage and differential movement between different types of materials, as a result of the increased building height; increased, dead, live, wind and seismic loads that are a consequence of taller building height; requirements for continuous stacked shearwall layouts; increased fire-resistance ratings for fire separations, as required for buildings of greater height and area; ratings for sound transmission, as required for buildings of multi-family residential occupancy, as well as other uses; potential for longer exposure to the elements during construction; mitigation of risk related to fire during construction; and modified construction sequencing and coordination, resulting from the employment of prefabrication technologies and processes. There are many alternative approaches and solutions to these new design and construction considerations that are associated with mid-rise wood construction systems. Reference publications produced by the Canadian Wood Council provide more detailed discussion, case studies and details for mid-rise design and construction techniques. For further information, refer to the following resources: Mid-Rise Best Practice Guide (Canadian Wood Council) 2015 Reference Guide: Mid-Rise Wood Construction in the Ontario Building Code (Canadian Wood Council) Mid-Rise 2.0 – Innovative Approaches to Mid-Rise Wood Frame Construction (Canadian Wood Council) Mid-Rise Construction in British Columbia (Canadian Wood Council) National Building Code of Canada Wood Design Manual (Canadian Wood Council) CSA O86 Engineering design in wood Wood for Mid-Rise Construction (Wood WORKS! Atlantic) Fire Safety and Security: A Technical Note on Fire Safety and Security on Construction Sites in British Columbia/Ontario (Canadian Wood Council)

FAQs

What do the experts have to say about wood-frame mid-rise construction? Graham Finch, Building Science Research Engineer Michael Green, Principal, Michael Green Architecture Mid-rise Wood Construction – a detailed look at a changing landscape (Part 1) Mid-rise Wood Construction – a detailed look at a changing landscape (Part 2) Seven-storey wood-frame earthquake test BC Housing is supporting wood-frame construction for seniors’ rental housing Is mid-rise and tall wood building construction a new phenomenon: Wood-frame and heavy timber construction (up to ten storeys) was the norm in the early 1900’s, and many of these buildings still exist and are in use in many Canadian cities. Check them out here: http://www.flickr.com/photos/bobkh/337920532/. Over the past 10 years, there is a revival in the use of wood for both mid-rise (up to six-storeys) and tall buildings. In British Columbia alone, as of December 2013, there were over 250 five- and six-storey wood product based mid-rise buildings either in the design or construction phase. Why have code change proposals? This 2015 building code change is not about favoring wood over other building materials; it’s about acknowledging, via the highly thorough code process, that science-based innovation in wood products and building systems can and will lead to more choices for builders and occupants. Are these buildings safe? Regardless of the building material in question, nothing gets built unless it meets code. Mid-rise wood-frame buildings reflect a new standard of engineering in that structural, fire and seismic concerns have all been addressed by the expert committees of the Canadian Commission on Building and Fire Codes. As an example, when it comes to concerns from firefighters, there is increased sprinkler protection for concealed spaces and balconies, greater water supply for fire protection, restrictions on types of building claddings used and increased consideration for access by firefighters . In the end, when occupied, these buildings fully meet the same requirements of the Building Code as any other type of construction from the perspective of health, safety and accessibility. What are some of the new safety provisions being proposed? Fire safety: Increased level of sprinkler / water protection: More concealed spaces sprinklered Balconies must be sprinklered Greater water supply for fire protection Non-combustible or limited combustible exterior wall cladding on 5th and 6th storey 25% of perimeter must face one street (within 15m of street) for firefighter access Seismic and wind provisions: Similar to BC Building Code Guidance (Appendix) on impact of increased rain and wind loads for 5- and 6-storey Acoustics: Requirements for Apparent Sound Transmission Class (ASTC) Supported by science from FPInnovations, NRC and many others. Doesn’t wood burn? No building material is impervious to the effects of fire. The proposed code changes go above and beyond the minimum requirements outlined in the NBCC. Health, safety, accessibility, fire and structural protection of buildings remain the core objectives of the NBCC and wood industry at large. What about construction site safety? The Canadian Wood Council has developed construction site fire safety guides which outline best practices and safety precautions to take during the construction phase of a building. Are mid-rise wood-frame buildings cost effective? For the most part, yes. Mid-rise wood-frame buildings are often a less expensive construction option for builders. This is good news for main-street Canada where land is so expensive. The recommended changes to the National Building Code of Canada (NBCC) would give the opportunity to erect safe, code compliant buildings that would otherwise not be possible. The net benefit of reduced construction costs is increased affordability for home buyers. In terms of new economic opportunity, the ability to move forward “now” creates new construction jobs in cities and supports employment in forestry communities. This also offers increased export opportunities for current and innovative wood products, where adoption in Canada provides the example for other countries.

Adhesives

Adhesives can also be referred to as resins. Many engineered wood products, including finger-joined lumber, plywood, oriented strand board (OSB), glulam, cross-laminated timber (CLT), wood I-joists and other structural composite lumber products, require the use of adhesives to transfer the stresses between adjoining wood fibres. Waterproof adhesives and heat resistant adhesives are commonly used in the manufacture of structural wood products. Advances in adhesive technology to address challenges associated with increased production rates, visual appearance, process emissions and environmental impact concerns, have resulted in a wider range of innovative structural adhesive products. It is imperative that this new generation of adhesives achieve the same level of performance as traditional structural wood product adhesives such as phenol-formaldehyde (PF) or phenol-resorcinol formaldehyde (PRF). Examples of different structural wood product adhesives families include, but are not limited to: Emulsion polymer isocyanate (EPI); One-component polyurethane (PUR); Phenolic resins such as phenol-formaldehyde (PF) and phenol-resorcinol formaldehyde (PRF). Various types of extenders such as walnut shell flour, Douglas fir bark flour, alder bark flour, and wood flour are sometimes used to reduce cost, control penetration into the wood fibre or moderate strength properties for the specific materials being bonded. There are several industry standards that may be used to evaluate the performance of structural wood product adhesives, including: CSA O112.6 Phenol and phenol-resorcinol resin adhesives for wood (high-temperature curing) CSA O112.7 Resorcinol and phenol-resorcinol resin adhesives for wood (room- and intermediate-temperature curing) CSA O112.9 Evaluation of adhesives for structural wood products (exterior exposure) CSA O112.10 Evaluation of adhesives for structural wood products (limited moisture exposure) CAN/CSA O160 Formaldehyde emissions standard for composite wood products ASTM D7247 Standard Test Method for Evaluating the Shear Strength of Adhesive Bonds in Laminated Wood Products at Elevated Temperatures ASTM D7374 Standard Practice for Evaluating Elevated Temperature Performance of Adhesives Used in End-Jointed Lumber

Bolts

Bolts are widely used in wood construction. They are able to resist moderately heavy loads with relatively few connectors. Bolts may be used in wood-to-wood, wood-to-steel and wood-to-concrete connection types. Some typical structural applications for bolts include: purlin to beam connections beam to column connections column to base connections truss connections timber arches post and beam construction pole-frame construction timber bridges marine structures Several types of bolts as shown in Figure 5.10 below, are used for wood construction with the hexagon head type being the most common. Countersunk heads are used where a flush surface is desired. Carriage bolts can be tightened by turning the nut without holding the bolt since the shoulders under the head grip the wood. Bolts are commonly available in imperial diameters of 1/4, 1/2, 5/8, 3/4, 7/8 and 1 inch. Bolts are installed in holes drilled slightly (1 to 2 mm) larger than the bolt diameter to prevent any splitting and stress development that could be caused by installation or subsequent wood shrinkage. Depending on the diameter, bolts are available in lengths from 75 mm (3″) up to 400 mm (16″) with other lengths available on special order. Bolts can be dipped or plated, at an additional cost, to provide resistance to corrosion. In exposed conditions and high moisture environments, corrosion should be resisted by using hot dip galvanized or stainless steel bolts, washers and nuts. Washers are commonly used with bolts to keep the bolt head or nut from crushing the wood member when tightening is taking place. Washers are not required with a steel side plate, as the bolt head or nut bears directly on the steel. Common types of washers are shown in Figure 5.11 below. Design information provided in CWC’s Wood Design Manual is based on bolts conforming to the requirements of ASTM A307 Standard Specification for Carbon Steel Bolts, Studs, and Threaded Rod 60 000 PSI Tensile Strength or Grade 2 bolts and dowels as specified under SAE J429 Mechanical and Material Requirements for Externally Threaded Fasteners. Download Figure 5.10 (and 5.11) as a PDF.

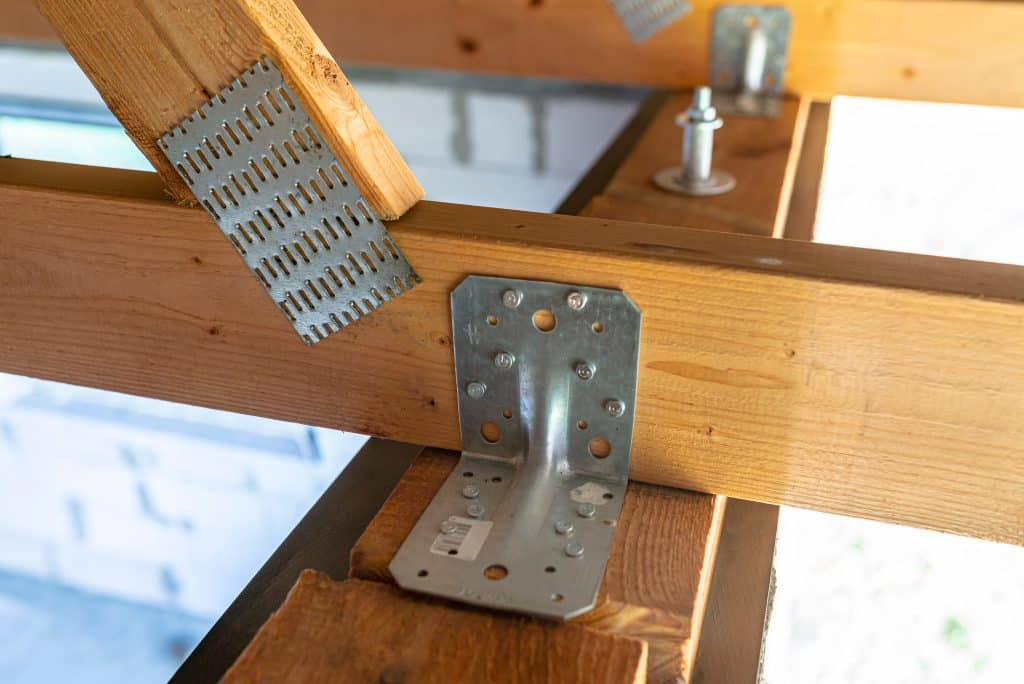

Framing Connectors

Framing connectors are proprietary products and include fastener types such as; framing anchors, framing angles, joist, purling and beam hangers, truss plates, post caps, post anchors, sill plate anchors, steel straps and nail-on steel plates. Framing connectors are often used for different reasons, such as; their ability to provide connections within prefabricated light-frame wood trusses, their ability to resist wind uplift and seismic loads, their ability to reduce the overall depth of a floor or roof assembly, or their ability to resist higher loads than traditional nailed connections. Examples of some common framing connectors are shown in Figure 5.6, below. Framing connectors are made of sheet metal and are manufactured with pre-punched holes to accept nails. Standard framing connectors are commonly manufactured using 20- or 18-gauge zinc coated sheet steel. Medium and heavy-duty framing connectors can be made from heavier zinc-coated steel, usually 12-gauge and 7-gauge, respectively. The load transfer capacity of framing connectors is related to the thickness of the sheet metal as well as the number of nails used to fasten the framing connector to the wood member. Framing connectors are suitable for most connection geometries that use dimensional lumber that is 38 mm (2″ nom.) and thicker lumber. In light-frame wood construction, framing connectors are commonly used in connections between joists and headers; rafters and plates or ridges; purlins and trusses; and studs and sill plates. Certain types of framing connectors, manufactured to fit larger wood members and carry higher loads, are also suitable for mass timber and post and beam construction. Manufacturers of the framing connectors will specify the type and number of fasteners, along with the installation procedures that are required in order to achieve the tabulated resistance(s) of the connection. The Canadian Construction Materials Centre (CCMC), Institute for Research in Construction (IRC), produce evaluation reports that document resistance values of framing connectors, which are derived from testing results. Figure 5.6 Framing Connectors For more information, refer to the following resources: Canadian Construction Material Centre, National Research Council of Canada Truss Plate Institute of Canada CSA S347 Method of Test for Evaluation of Truss Plates used in Lumber Joints ASTM D1761 Standard Test Methods for Mechanical Fasteners in Wood Canadian Wood Truss Association

Oriented Strand Board (OSB)

Oriented Strand Board (OSB) is a widely used, versatile structural wood panel. OSB makes efficient use of forest resources, by employing less valuable, fast-growing species. OSB is made from abundant, small diameter poplar and aspen trees to produce an economical structural panel. The manufacturing process can make use of crooked, knotty and deformed trees which would not otherwise have commercial value, thereby maximizing forest utilization. OSB has the ability to provide structural performance advantages, an important component of the building envelope and cost savings. OSB is a dimensionally stable wood-based panel that has the ability to resist delamination and warping. OSB can also resist racking and shape distortion when subjected to wind and seismic loadings. OSB panels are light in weight and easy to handle and install. OSB panels are primarily used in dry service conditions as roof, wall and floor sheathing, and act as key structural components for resisting lateral loads in diaphragms and shearwalls. OSB is also used as the web material for some types of prefabricated wood I-joists and the skin material for structural insulated panels. OSB can also be used in siding, soffit, floor underlayment and subfloor applications. Some specialty OSB products are made for siding and for concrete formwork, although OSB is not commonly treated using preservatives. OSB has many interleaved layers which provide the panel with good nail and screw holding properties. Fasteners can be driven as close as 6 mm (1/4 in) from the panel edge without risk of splitting or breaking out. OSB is a structural mat-formed panel product that is made from thin strands of aspen or poplar, sliced from small diameter roundwood logs or blocks, and bonded together with a waterproof phenolic adhesive that is cured under heat and pressure. OSB is also manufactured using the southern yellow pine species in the United States. Other species, such as birch, maple or sweetgum can also be used in limited quantities during manufacture. OSB is manufactured with the surface layer strands aligned in the long panel direction, while the inner layers have random or cross alignment. Similar to plywood, OSB is stronger along the long axis compared to the narrow axis. This random or cross orientation of the strands and wafers results in a structural engineered wood panel with consistent stiffness and strength properties, as well as dimensional stability. It is also possible to produce directionally-specific strength properties by adjusting the orientation of strand or wafer layers. The wafers or strands used in the manufacture of OSB are generally up to 150 mm (6 in) long in the grain direction, 25 mm (1 in) wide and less than 1 mm (1/32″) in thickness. In Canada, OSB panels are manufactured to meet the requirements of the CSA O325 standard. This standard sets performance ratings for specific end uses such as floor, roof and wall sheathing in light-frame wood construction. Sheathing conforming to CSA O325 is referenced in Part 9 of the National Building Code of Canada (NBC). In addition, design values for OSB construction sheathing are listed in CSA O86, allowing for engineering design of roof sheathing, wall sheathing and floor sheathing using OSB conforming to CSA O325. OSB panels are manufactured in both imperial and metric sizes, and are either square-edged or tongue-and-grooved on the long edges for panels 15 mm (19/32 in) and thicker. For more information on available sizes of OSB panel, refer to the document below. For more information on OSB, please refer to the following resources: APA – The Engineered Wood Association National Building Code of Canada CSA O86 Engineering design in wood CSA O325 Construction sheathing CSA O437 Standards on OSB and Waferboard PFS TECO Example specifications for oriented strand board (OSB) Oriented Strand Board (OSB) Grades Oriented Strand Board (OSB) Manufacture Oriented Strand Board (OSB) Quality Control Oriented Strand Board (OSB) Sizes Oriented Strand Board (OSB) Storage and Handling

Preservative Treated Wood

Preservative-treated wood is surface coated or pressure impregnated with chemicals that improve the resistance to damage that can result from biological deterioration (decay) due to the action of fungi, insects, and microorganisms. Preservative treatment offers a means for improving the resistance and extending the service life of those wood species which do not have sufficient natural resistance under certain in-use conditions. It is possible to extend the service life of untreated wood products by up to ten times through the use of preservative treatment. Preservative-treated wood can be used for exterior structures that require resistance to fungal decay and termites, such as: bridges, utility poles, railway ties, docks, marinas, fences, gazebos, pergolas, playground equipment, and landscaping. Four factors are necessary to sustain life for wood destroying fungi; a suitable food supply (wood fibre), a sustained minimum wood moisture content of about 20 percent (common for exterior use conditions), exposure to air, and a favourable temperature for growth (cold temperatures inhibit, but do not eliminate fungi growth). Preservative treatment is effective because it removes the food supply by making it poisonous to the fungi and wood destroying insects such as termites. An effective wood preservative must have the ability to penetrate the wood, neutralize the food supply of fungi and insects, and be present in sufficient quantities in a non-leachable form. Effective preservatives will also kill existing fungi and insects that might already exist in the wood. There are two basic methods of treating wood; with and without pressure. Non-pressure methods include the application of preservative by brushing, spraying or dipping the piece of wood. These superficial treatments do not result in deep penetration or large absorption of preservative and are typically restricted to field treatment during construction. Deeper and more thorough penetration is achieved by driving the preservative into the wood cells with pressure. Various combinations of pressure and vacuum are used to force adequate levels of chemical into the wood. For a wood preservative to function effectively it must be applied under controlled conditions, to specifications known to ensure that the preservative-treated wood will perform under specific in-use conditions. The manufacture and application of wood preservatives are governed by the CSA O80 series of standards. CSA O80 provides information on the wood species that may be treated, the types of preservatives and the retention and penetration of preservative in the wood that must be achieved for the use category or application. To ensure that the specified degree of protection will be provided, a preservative-treated wood product may bear a stamp indicating the suitability for a specific use category. Wood preservatives in Canada are governed by the Pest Control Products Act and must be registered with the Pest Management Regulatory Agency (PMRA) of Health Canada. Common types of wood preservatives that are used in Canada include chromated copper arsenate (CCA), alkaline copper quaternary (ACQ), copper azole (CA), micronized copper azole (MCA), borates, creosote, pentachlorophenol, copper naphthenate and zinc naphthenate. Acid salts can lessen the strength of wood if they are present in large concentrations. The concentrations used in preservative-treated wood are sufficiently small so that they do not affect the strength properties under normal use conditions. In some cases, the specified strength and stiffness of wood is reduced due to incising of the wood during the pressure impregnation process (refer to CSA O86 for further information on structural design reduction factors). Hot dipped galvanized or stainless steel fasteners and connection hardware are usually required to be used in conjunction with preservative-treated wood. There may be additional materials, such as polymer or ceramic coatings, or vinyl or plastic flashings that are suitable for use with preservative-treated wood products. The manufacturer should be consulted prior to specification of fasteners and connection hardware. For further information, refer to the following resources: www.durable-wood.com Wood Preservation Canada Canadian Wood Preservation Association CSA O80 Series Wood preservation CSA O86 Engineering design in wood Pest Management Regulatory Agency of Health Canada American Wood Protection Association

Nails

Nailing is the most basic and most commonly used means of attaching members in wood frame construction. Common nails and spiral nails are used extensively in all types of wood construction. Historical performance, along with research results have shown that nails are a viable connection for wood structures with light to moderate loads. They are particularly useful in locations where redundancy and ductile connections are required, such as loading under seismic events. Typical structural applications for nailed connections include: wood frame construction post and beam construction heavy timber construction shearwalls and diaphragms nailed gussets for wood truss construction wood panel assemblies Nails and spikes are manufactured in many lengths, diameters, styles, materials, finishes and coatings, each designed for a specific purpose and application. In Canada, nails are specified by the type and length and are still manufactured to Imperial dimensions. Nails are made in lengths from 13 to 150 mm (1/2 to 6 in). Spikes are made in lengths from 100 to 350 mm (4 to 14 in) and are generally stockier than nails, that is, a spike has a larger cross-sectional area than an equivalent length common nail. Spikes are generally longer and thicker than nails and are generally used to fasten heavy pieces of timber. Nail diameter is specified by gauge number (British Imperial Standard). The gauge is the same as the wire diameter used in the manufacture of the nail. Gauges vary according to nail type and length. In the U.S., the length of nails is designated by “penny” abbreviated “d”. For example, a twenty-penny nail (20d) has a length of four inches. The most common nails are made of low or medium carbon steels or aluminum. Medium-carbon steels are sometimes hardened by heat treating and quenching to increase toughness. Nails of copper, brass, bronze, stainless steel, monel and other special metals are available if specially ordered. Table 1, below, provides examples of some common applications for nails made of different materials. TABLE 1: Nail applications for alternative materials Material Abbreviation Application Aluminum A For improved appearance and long life: increased strain and corrosion resistance. Steel – Mild S For general construction. Steel – Medium Carbon Sc For special driving conditions: improved impact resistance. Stainless steel, copper and silicon bronze E For superior corrosion resistance: more expensive than hot-dip galvanizing. Uncoated steel nails used in areas subject to wetting will corrode, react with extractives in the wood, and result in staining of the wood surface. In addition, the naturally occurring extractives in cedars react with unprotected steel, copper and blued or electro-galvanized fasteners. In such cases, it is best to use nails made of non-corrosive material, such as stainless steel, or finished with non-corrosive material such as hot-dipped galvanized zinc. Table 2, below, provides examples of some common applications for alternative finishes and coatings of nails. TABLE 2: Nail applications for alternative finishes and coatings Nail Finish or Coating Abbreviation Application Bright B For general construction, normal finish, not recommended for exposure to weather. Blued Bl For increased holding power in hardwood, thin oxide finish produced by heat treatment. Heat treated Ht For increased stiffness and holding power: black oxide finish. Phoscoated Pt For increased holding power; not corrosion resistant. Electro galvanized Ge For limited corrosion resistance; thin zinc plating; smooth surface; for interior use. Hot-dip galvanized Ghd For improved corrosion resistance; thick zinc coating; rough surface; for exterior use. Pneumatic or mechanical nailing guns have found wide-spread acceptance in North America due to the speed with which nails can be driven. They are especially cost effective in repetitive applications such as in shearwall construction where nail spacing can be considerably closer together. The nails for pneumatic guns are lightly attached to each other or joined with plastic, allowing quick loading nail clips, similar to joined paper staples. Fasteners for these tools are available in many different sizes and types. Design information provided in CSA O86 is applicable only for common round steel wire nails, spikes and common spiral nails, as defined in CSA B111. The ASTM F1667 Standard is also widely accepted and includes nail diameters that are not included in the CSA B111. Other nail-type fastenings not described in CSA B111 or ASTM F1667 may also be used, if supporting data is available. Types of Nails For more information, refer to the following resources: International, Staple, Nail, and Tool Association (ISANTA) CSA O86 Engineering design in wood CSA B111 Wire Nails, Spikes and Staples ASTM F1667 Standard Specification for Driven Fasteners: Nails, Spikes and Staples

Screws

Wood screws are manufactured in many different lengths, diameters and styles. Wood screws in structural framing applications such as fastening floor sheathing to the floors joists or the attachment of gypsum wallboard to wall framing members. Wood screws are often higher in cost than nails due to the machining required to make the thread and the head. Screws are usually specified by gauge number, length, head style, material and finish. Screw lengths between 1 inch and 2 ¾ inch lengths are manufactured in ¼ inch intervals, whereas screws 3 inches and longer, are manufactured in ½ inch intervals. Designers should check with suppliers to determine availability. Design provisions in Canada are limited to 6, 8, 10 and 12 gauge screws and are applicable only for wood screws that meet the requirements of ASME B18.6.1. For wood screw diameters greater than 12 gauge, design should be in accordance with the lag screw requirements of CSA O86. Screws are designed to be much better at resisting withdrawal than nails. The length of the threaded portion of the screw is approximately two-thirds of the screw length. Where the wood relative density is equal to or greater than 0.5, lead holes, at least the length of the threaded portion of the shank, are required. In order to reduce the occurrence of splitting, pre-drilled holes are recommended for all screw connections. The types of wood screws commonly used are shown in Figure 5.4, below. For more information on wood screws, refer to the following resources: ASME B18.6.1 Wood Screws CSA O86 Engineering design in wood