Building Confidence in Low Carbon Construction De-risking Mass Timber

Course Overview This presentation explores how insurance can unlock opportunity by aligning risk strategies with sustainability goals. It will provide an analysis of the Canadian and Global insurance market and explain why mass timber has become such a hot topic for insurers. Critical risk mitigation strategies will be discussed as well as various options on how to address many of the more common moisture management problems encountered in construction. Learning Objectives Why is Mass Timber a focus area of the insurance industry? How do I design and position my project to achieve cost effective risk transfer? What are some of the most common types of insured loss and how do I avoid them? Course Video Speakers Bio Alicia Clendenan SVP – National Director of Sustainable Construction Aon Alicia is a socially conscious business professional with a passion for complex construction and infrastructure projects. She leads Aon’s Sustainable and Alternative Construction practice across Canada and has more than 15 years of risk and insurance advisory experience. She also serves as Aon’s global mass timber working group chair and is involved in a number of industry initiatives aimed at reducing barriers to insurance for mass timber construction as well as enhancing both the breadth of coverage offered by insurers and improving the industry adopted best practices for risk mitigation in construction.

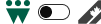

Unlocking Affordable Timber: Innovations in Structure, Prefabrication, and Code

Course Overview Bond Tower is a 7-storey mixed-use prototype that asks a critical question: how can mass timber be made cost-effective in the Prairies, where supply chains are limited, demand is low, and timber construction is often reserved for flagship projects. Funded by the Green Construction through Wood Program from Natural Resources Canada, the project develops both prototypes and a built demonstration to advance affordable timber solutions in a region underserved by the current market. The design leverages nail-laminated timber (NLT) as its primary system, applied in diagrid trusses, floor assemblies, and shear walls. NLT presents a cost-effective alternative to other manufactured products and provides great versatility due to its custom nature. Lateral and gravity-induced forces are carried by a diagrid timber truss fabricated from readily available dimensional lumber and using simple mechanical fasteners. Floor assemblies comprised of NLT are constructed without a concrete topping or proprietary sound attenuation systems, reducing both cost and embodied carbon. Prefabricated wall panels, stairs, and modular service pods further minimize waste and construction time. Another challenge lies in building code classification. Currently, all structures above six storeys are deemed high-rise, requiring costly and difficult to achieve [in timber] two-hour fire-resistance ratings and fire-safety systems. The Bond Tower design team, working with code consultants, is developing an alternative solution that leverages the inherent 1.25-hour FRR of NLT floor assemblies. This approach suggests a pathway toward a new mid-rise category, making timber projects of seven or eight storeys more financially viable. Alongside a single-stair configuration, which can increase efficiency by reducing non-rentable floor area, these strategies point to a replicable model for affordable timber construction across Canada. Learning Objectives Learn how NLT and prefabrication strategies can reduce cost, waste, and construction time, making timber more feasible in the Prairies. Explore structural detailing approaches that simplify connections and reduce cost, while addressing fire, durability, and acoustic performance in timber design. Examine how alternative solutions can improve the financial feasibility of 6–8 storey timber projects and support broader code updates across Canada. Course Video Speakers Bio Sasa Radulovic, AIBC MAA OAA SAA AAA NSAA FRAIC LEED AP Partner, Architect 5468796 Architecture Sasa Radulovic co-founded the Winnipeg-based practice 5468796 Architecture with Johanna Hurme in 2007. A talented designer, Sasa guides the office in seeking projects that explore density, affordability, and sustainability through non-traditional means and a dynamic design approach. Recent institutional appointments include Visiting Professor-Morgenstern Chair with the Faculty of Architecture at the Illinois Institute of Technology in Chicago. Ken Borton, MAA RAIC Principal 5468796 Architecture Upcoming… Oliver Brandt, P.Eng Associate Fast + Epp Upcoming…

Early Mass Timber Collaboration: A Journey from Design Assists Pre-Construction through Construction

Course Overview In this session attendees will be taken through the evolution of the mass timber structure design for the Sam Centre at the Calgary Stampede. We will explore the varied forms of collaboration from design and pre-construction through construction to completion. During the talk the value of collaboration will be examined from a design assist trade to the early onboarding of a mass timber erector, to the engagement of a mass timber specialists examining topics from erection tolerances to moisture and construction protection, to storage procedures, to fire retardant impregnation, and the aesthetic and performance outcome of each. Particular attention will be paid to how the process of collaboration at the various stages aided the design and successful execution of the mass timber connection details. A tour of the project could also be offered given its proximity to the conference. The Sam Centre is a year-round immersive experience that brings the ‘world of the Calgary Stampede’ – past, present and future – to life through technology, story-making, and Western hospitality. The use of Mass timber was a key strategy in connecting to the history of the Stampede and its historic structures. Sam Centre is a linear volume characterized by a large horizontal pitched roof. The structure uses a repetitive hybrid steel frame with exposed mass timber beams and a Nail Laminated Timber Roof Deck, adding warmth to the interior and creating a distinct profile offering a modern yet durable nod to traditional barn construction. Creating deep overhanging soffits which mitigate heating and cooling loads, the roof also evokes the welcoming verandahs of traditional Alberta architecture. Learning Objectives Learn how design assist supported the design of the mass timber connections and how those details would be built to ensure the structure was built efficiently and effectively. Learn about the importance of bringing on a mass timber erector early in the design process to ensure that the construction system and any tolerances required are correctly captured in drawings. Understand the value of a collaborative approach between design team, consultants, trades, and building science team to ensure all facets of mass timber construction are noted across project phases. Course Video Speakers Bio Jeff Geldart, AAA, OAA Associate Diamond Schmitt Jeff Geldart believes having a thorough understanding of the client’s goals and objectives is critical to developing a design that best meets their needs and expectations. That understanding becomes the root of any great piece of architecture. If the building does not meet the needs of its occupants, then the rest is superfluous. Throughout his professional career Jeff has worked with both institutional and private sector clients. Some of his more notable institutional projects have included work with Wentworth County and Canada’s Department of Foreign Affairs and International Trade. One Developments, Lifetime Developments and Kylemore Communities are among his residential accomplishments. This broad and range of experience has allowed him to enhance his drive for achieving design excellence while at the same time rigorously working to consistently meet schedules, budgets, and ultimately project execution. Jeff demonstrates a phenomenal capability technically, aesthetically, and managerially on his projects. Since joining Diamond Schmitt in 2019, Jeff has worked as the Senior Architect on the Ottawa Public Library and Library Archives Canada Joint Facility and the Okotoks Arts and Learning Campus in Alberta. Jeff is currently based in Calgary. Mark Grimes, P.Eng, PMP Senior Project Manager EllisDon Mark Grimes is a Senior Project Manager at EllisDon, originally graduating from Trinity College Dublin with a degree in Civil and Structural Engineering – Mark moved to Canada in 2010 and has spent the last 15 years working primarily in Alberta on a wide range of projects ranging from highrise tower construction to luxury hydrotherapy spas.

Design Best Practices for Mid-Rise Light Wood Frame Structures

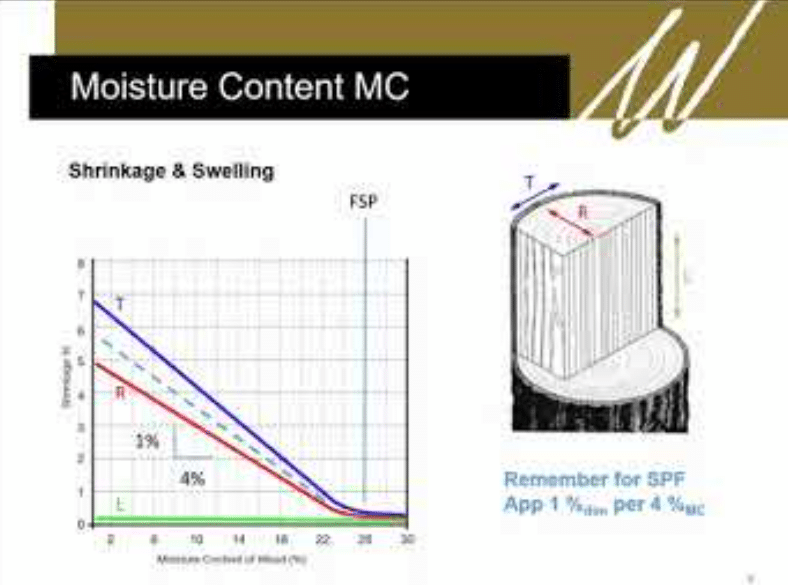

Course Overview Light wood frame (LWF) construction is an accessible, cost-effective, low-carbon solution for mid-rise multi-family buildings. This session will clarify fundamental differences in approach between traditional low-rise LWF construction and modern mid-rise construction methods. LWF is an attractive option for mid-rise development and participants will gain practical insights into design efficiencies, from meeting seismic demands and other key structural considerations to how engineered wood products and specialty hardware can be used to optimize design. The session will also explore prefabrication strategies, highlighting the challenges and opportunities offsite construction presents for streamlined, higher-quality construction. Whether attendees are new to mid-rise wood design or looking to optimize their next project, this session will share valuable information they can apply to their next mid-rise building. Learning Objectives Distinguish key differences between traditional low-rise and modern mid-rise light wood frame construction, including changes in design loads, seismic requirements, and code updates. Apply practical design strategies to optimize mid-rise wood structures—such as efficient stacked framing, engineered wood products, specialty hardware, and solutions for wood shrinkage and differential movement. Evaluate prefabrication and offsite construction methods for mid-rise projects, identifying both challenges and opportunities to improve construction quality, speed, and coordination. Course Video Speakers Bio Sean Henry Director – Mid-Rise, Principal Tacoma Engineers Sean is the Director of Mid-Rise and a Principal at Tacoma Engineers, bringing 20 years of structural engineering experience to the role. Since joining the firm in 2005, Sean has led the design of a wide range of building types, with a particular focus on mid-rise developments including multi-family, seniors and affordable housing projects. He is especially recognized for his expertise in light wood frame construction with multiple projects designed and built since the adoption of 6 storey wood framed buildings in Ontario. He also has extensive experience with cold-formed steel, structural steel, reinforced concrete, precast, and concrete block building systems. Sean focuses on delivering practical, efficient structural solutions that support design intent while meeting the demands of constructability and cost-effectiveness.

Timber and Off-Site Construction

Course Overview Join WoodWorks and prefab panel supplier, Ron Anderson + Sons, as they discuss strategies for navigating the world of off-site construction, explaining the challenges and benefits of prefabrication and how they impact the design and construction process. Learn about different strategies for navigating code compliance and coordinating with a prefabricated component supplier. The discussion will also cover common constraints like high seismic forces and high efficiency envelopes and how to address these with off-site construction. This one-hour presentation will provide a deeper understanding of the off-site construction process and its implications for your role in designing and constructing wood buildings. Learning Objectives Learn when off-site construction can deliver cost and schedule savings. Learn how to ensure design coordination and specifications align with project requirements and prefabricated component supplier constraints. Learn how construction strategies and detailing are affected when using prefabricated components and how to ensure successful project outcomes. Course Video Speakers Bio Derek Ratzlaff, P.Eng., Struct.Eng., PE Technical Director WoodWorks BC Derek began his career in the wood industry in high school working on single and multi-family light wood frame construction. After university, and almost 20 years of structural consulting experience, Derek has worked in all types of wood construction and played key roles in the delivery of iconic BC wood structures including the Richmond Olympic Oval and Grandview Heights Aquatic Centre. He brings his experience in design and construction to support the industry as a Technical Director for Woodworks BC. Jack Downing President and CEO Ron Anderson and Sons Ltd. Wood Framing Jack’s journey in the framing industry spans over 20 years. He joined RAS in 2012 and his adeptness in orchestrating large sites and coordinating multiple crews immediately made him an invaluable asset to the company. His dedication and strong leadership led to his appointment as President and CEO of RAS in 2019. His journey from a skilled professional to respected industry leader exemplifies the ethos of growth and opportunity that defines RAS’s company culture. Under Jack’s leadership RAS is poised for continuous growth and innovation in the construction industry.

Exploring the Feasibility of Point-Supported Mass Timber for Tallwood Construction

Course Overview This session examines the growing potential of point-supported mass timber systems in tall building construction, contrasting them with traditional timber framing and conventional steel and concrete approaches. It highlights regulator advancements, the role of mass timber in addressing mid-density housing needs, and the structural fundamentals of gravity and lateral systems. Through cost and schedule comparisons, design principles like bi-axial bending and punching shear, and insights from ongoing Canadian codification efforts, the presentation offers a comprehensive overview supported by real-world projects such as VAHA Burrard and BCIT Tall Timber. Learning Objectives Evaluate the opportunities and constraints for point-supported mass timber when compared to traditional timber framing schemes. Analyze the schedule and cost benefits of point-supported mass timber systems versus steel and concrete in tall construction projects. Explore state-of-the-art design methodologies and ongoing efforts towards codification in Canada. Course Video Speakers Bio Carla Dickof, P.Eng., M.A.Sc. Associate Principal | Director of Research & Development Fast+Epp Carla Dickof is the Associate Principal & Director of Research and Development at Fast + Epp, where she leads the Testing Team at Fast + Epp’s R&D hub, Concept Lab, and uses the data gleaned from research programs to regularly contribute to academic journals and conferences. Carla completed her Master’s degree studies at the University of British Columbia, where her thesis research focused on hybrid systems, specifically those combining steel and mass timber (CLT). Her experience as an engineer spans commercial, recreational, educational, and residential projects – and, since joining Fast + Epp in 2012, Carla has gained a robust fluency in all major building materials, including concrete, steel, light-framed wood, heavy timber, and mass timber. Her understanding of building physics and materials brings invaluable insights to her projects. Alejandro Coronado, P.Eng. Technical Advisor WoodWorks BC Alejandro Coronado is a Technical Advisor with a multidisciplinary background spanning contracting, supply, and consulting engineering. With both a Diploma and a Bachelor’s Degree in Structural Engineering from BCIT, Alejandro began his career in single-family residential design and steadily advanced to contribute to landmark projects such as the Centre Block Base Isolation at Parliament Hill, the UBC Museum of Anthropology Great Hall Renewal, the Royal BC Museum PARC Campus, and a mass timber campus in Silicon Valley. Initially drawn to mass timber for its expressive architectural potential, Alejandro quickly recognized its broader value in addressing today’s social and environmental challenges. Through many years of hands-on experience, Alejandro has become a champion for sustainable construction and simple yet effective structural solutions.

Seismic Solutions for Resilient Wooden Structures

Course Overview Timber structures are getting bigger and higher with the availability of economical mass timber products on the market. Timber is also very attractive to designers in seismic-prone regions because of its advantageous strength-to-weight ratio. However, resilience becomes an issue as traditional ductility strategies are not low-damage and result in loss of stiffness following a seismic event. In this presentation, basic concepts of seismic engineering and structural ductility are reviewed. The drawbacks of typical timber connections designed to provide ductility to timber structures are identified along with the long-term consequences. Resilient seismic dampers provide a solution to this issue. They are self-centering friction devices that do not get damaged within their ultimate capacity. The technology behind the resilient friction dampers is explained along with their application in different structural case studies. Learning Objectives Understand fundamental seismic engineering concepts. Identify limitations of conventional timber ductility strategies. Evaluate the role and performance of resilient seismic dampers. Course Video Speaker Bio Pierre Quenneville Professor of timber design, The University of Auckland CTO, Tectonus Ltd. David Bowick has received many industry honours since he began his career in 1990. His inventive approach to design has made him sought-after, particularly when a project calls for innovative solutions. He is a three-time recipient of the WoodWorks Building the Future engineer award, and has received awards for his work in wood, concrete and architectural steel. Dozens of projects he has worked on have been granted awards in the field of architecture, such as the Perimeter Institute for Theoretical Physics and the French River Visitors Centre (both recipients of the Governor General’s Award). An avid teacher, David is an adjunct professor in the Masters in Architecture program at the University of Toronto. He is a frequent guest speaker on the topics of architecture and engineering, and contributes to the industry through committees and events. His writing has appeared in several publications, including Concrete Toronto. David is a licensed professional engineer in the provinces of Ontario, British Columbia, Alberta and New Brunswick. He is a member of the Canadian Standards Association Technical Committee on CAN/CSA-O86, Engineering Design in Wood and a member of the Technical Committee responsible for the Engineering Guide for Wood Frame Construction.

Shearwall Connections and Lateral Systems for Wood Buildings

Course Overview This comprehensive course delves into the latest advancements in wood shearwall systems and connections, featuring critical updates from the 2020 National Building Code of Canada (NBCC). This course will cover essential topics, including advancements in lateral systems and rod holdowns, and provide a step-by-step approach to accurately calculating deflection for rod holdowns. Dive into key details on relevant connections and fasteners that enhance performance and resilience. The session will culminate with a overview of the outcomes of a groundbreaking 10-storey mass timber seismic test conducted in San Diego as part of the NHERI Tall Wood Project, showcasing how these innovations perform under real-world conditions. This webinar is designed for engineers, architects, and construction professionals looking to stay current with advancements in seismic design for wood structures. Learning Objectives Gain insights into the latest advancements in seismic and lateral force-resisting systems for timber construction. Learn effective methods for calculating deflection in rod hold-down systems, ensuring compliance with structural performance standards. Explore best practices and expert recommendations for specifying connections in shearwalls to optimize strength and resilience. Understand key findings from the NHERI TallWood test, highlighting lessons from the tallest mass timber building ever tested on a shake table. Course Video Speaker Bio Tim Wagner, P.Eng., MBA Field Engineer Simpson Strong-Tie Tim joined Simpson Strong-Tie in 2014 as an EIT, and earned his Professional Engineering designation in 2018. His primary role is building relationships with specifiers in western Canada, with major focuses on connections, lateral systems fasteners and anchors.

Joining Tradition and Innovation with Mass timber Connections

Course Overview An overview of traditional, state of the art and innovative wood fasteners and connectors. This course is of particular interest to structural engineers and design professionals interested in structural engineering. Learning Objectives Wood Properties and their influence on timber connection design. Overview of traditional, state-of-the-art and innovative fasteners and connectors. Ductility and durability aspects in connection with dowel type fasteners. Modern carpentry – a resurrection of traditional framing through CNC. Best practices for the design of mass timber connections. Course Video Speaker Bio Patrick Geers Senior Structural Designer, Head of Quality Control Western Archrib As the company’s senior engineering designer Patrick is in charge of the design of structural wood systems including fabricated steel connections and hardware He is involved in the development and presentation of building proposals to support sales efforts and cooperates with the production team to develop manufacturing solutions In addition, he is responsible for the supervision of quality control department Patrick has over 17 years experience in the glulam industry an currently sits on CSA 086 Sub-committee.

Diversify Your Structural Portfolio: Wood in Low-Rise Commercial Construction

Course Overview This course will explore the use cases for incorporating more wood into a sector that is typically dominated by structural steel construction. We will look at Light Wood Framing (LWF), Structural Composite Lumber (SCL), Mass Timber (MT), and Hybrid Systems that may incorporate any or all of these materials, as well as structural steel. What is important is using the right material in the right application. Several examples from the CWC Publication “Low-Rise Commercial Construction in Wood: A guide for Architects and Engineers”, as well as real project examples from the presenter. Learning Objectives Identify strengths and weaknesses of various wood products. Learn to select the right wood material/system for the most efficient and cost effective structure. Highlight critical details and identify potential red flags to ensure a successful project. Provide useful examples, resources and tools for the practitioner to add to their “tool belt”. Course Video Speaker Bio Alex Nowakowksi Engineer, Senior Associate, and Barrie Team Lead Tacoma Engineers Alex is a Professional Engineer, Senior Associate, and Barrie Team Lead for Tacoma Engineers. Alex has been with Tacoma Engineers since 2012. As a Senior Structural Engineer and Project Manager, Alex has been the Primary Structural Engineer and Specialty Structural Engineer on a wide variety of wood projects in the Commercial, Institutional, Multi-Family, Agricultural and Residential Sectors.

Advancing North American Mass Timber Projects: Harnessing the Strength of Local Expertise

Course Overview As global adoption of mass timber construction accelerates, a growing number of solutions are available in the marketplace that can contribute to the success of your project. This session, presented by Simpson Strong-Tie, will explore some of the unique challenges faced by North American projects and some of the domestically developed solutions available to meet those challenges. Learning Objectives Understand the need for greater tolerance on concealed beam hangers, the importance of ensuring connectors are easy to install, and the specific requirements for large elements in North American buildings. Understand the advantages domestic suppliers can bring to your project, including the rapid delivery of hardware to job sites. Learn about the necessity for effective installation tools and processes tailored to the scale of large North American projects. Learn about the need for effective moisture mitigation and the systems and strategies that can prevent unnecessary exposure of mass timber to the elements during construction. Course Video Speaker Bio Adrian Mitchell Chair of Simpson’s internal Mass Timber Focus Market Committee Simpson Strong-Tie Adrian is a mass timber and off-site business specialist with a principal focus on the rapidly expanding mass timber segment, for which he serves as Chair of Simpson’s internal Mass Timber Focus Market Committee. Adrian has spent the bulk of his 20-year career in the off-site, mass timber, and modular spaces, primarily as a business development leader and private consultant. With professional experiences ranging from heavy civil, oil and gas, high-end custom homes to large-scale mass timber missed-use projects and artificial intelligence in BIM, he has a unique and well-rounded background in wood and steel applications in off-site construction. Adrian is a native of Vancouver, Canada, and a graduate of the British Columbia Institute of Technology’s School of Business, he enjoys all the typical Canadian pastimes like playing hockey, building things from wood, and mountain biking.

Connections Course – US

The Connections Course provides an introduction to the WoodWorks Connections Program, a tool designed to assist engineers and designers in the creation and evaluation of wood connections. This course covers the design of new connections using bolts, nails, rivets, or shear plates and explains how to assess their capacity.You will gain an understanding of the program’s functionality, its application in real-world scenarios, and best practices for optimizing wood connections. Course Learning Outcomes By the end of this course, you will be able to: Course Structure This course consists of two (2) lessons. Each lesson is comprised of a lesson overview, learning outcomes, instructional videos, assessment questions and an assignment. Through these elements, you will gain practical experience in using the Connections Woodworks Program for real-world applications. Once you have completed all assessment questions and assignment submissions, a certificate of completion will be digitally awarded. Time for Completion This course is comprised of 2 videos for a total run time of 8:12 minutes. To complete the assessments in this course you can expect to spend ~ 20 minutes. Program Download In order to complete this course you will need to download a trial version of the Connections Program. Complete these steps to download the program: *Note: the trial version of the program is only valid for 10 days upon installation.