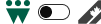

FRAMEWORK for Success: Prefabricated Wood Systems and Design Innovation

Course Overview This presentation explores the transformative impact of prefabricated light wood frame construction systems in multi-residential development, focusing on VanMar’s FRAMEWORK methodology and its application in the new 150 Wissler Road project in Waterloo. FRAMEWORK is a highly efficient, panelized light wood frame system designed for buildings up to six storeys, delivering rapid, sustainable, and cost-effective construction that meets and exceeds energy and greenhouse gas reduction targets. The session will highlight VanMar’s extensive experience in affordable housing, the advantages of offsite prefabrication, and the collaborative process that accelerates project delivery. Learning Objectives Participants will understand the benefits of prefabricated wood frame construction for multi-residential buildings. Participants will understand the FRAMEWORK system’s approach to speed, cost-effectiveness, and sustainability. Participants will be shown how collaborative offsite construction methods accelerated the 150 Wissler Road project. Participants will learn strategies for overcoming design challenges and achieving efficiencies in fire walls, shafts, and acoustics. Course Video Speakers Bio Jordan Zekveld Director of Preconstruction VanMar Constrcutors ON Jordan is a construction and development professional with deep experience in estimating, preconstruction, and cost strategy for multi-unit residential projects. At VanMar Constructors, he helps developers, REITs, and non-profits bring condominium, rental, and affordable housing projects from concept to construction. Drawing on VanMar’s integrated design-build expertise, Jordan leads collaborative preconstruction processes that align design intent, feasibility, and cost efficiency. His experience spans concrete high-rise and innovative mid-rise wood-frame developments, including the Framework system — VanMar’s sustainable, fast, and cost-effective building solution. With a focus on clarity, constructability, and long-term value, Jordan works at the intersection of planning, design, and execution to help deliver housing that’s efficient, affordable, and built to last. Mike Philips Executive Director Ontario Structural Wood Association (OSWA) Mike Phillips has served as Executive Director of OSWA since 2008. Under his leadership, the association has evolved from a truss-fabricator-focused group into Ontario’s leading voice for structural wood component manufacturing. Today, the province is home to 70 certified truss plants and 40 wood-panel manufacturers, with engineered wood products now the preferred choice for floor systems. At the same time, Ontario’s building code has never been more prepared to accommodate advanced wood-construction methods. Mike is a strong advocate for the industrialization of construction and the expanding role of off-site building systems—critical drivers of wood construction’s future growth. Paul Marchesani Operations Manager Panelized Building Solutions Inc. Paul Marchesani is the Vice President of Panelized Building Solutions Inc., a family run business where he plays a key leadership role in driving operational excellence, strategic growth, and project execution across the company. Known for his strong work ethic, hands-on approach, and deep industry knowledge, Paul oversees day-to-day operations while supporting long-term planning that aligns with the company’s vision. Before joining Panelized Building Solutions, Paul held key roles in project management and operations within manufacturing and construction environments, where he oversaw production teams, implemented process improvements, and helped streamline workflow efficiencies. His ability to manage both people and complex technical projects made him a natural fit for leadership. Respected by colleagues, clients, and trade partners alike, Paul combines technical expertise with strong leadership, making him an essential pillar of the company’s continued success.

Mid rise Engineering Considerations for Engineered Wood Products

Course Overview While many designers are familiar with engineered wood products such as I‐joists and structural composite lumber, it is important to understand the structural requirements associated with each in order to achieve proper performance—especially in mid‐rise Construction. With an emphasis on products used in commercial and multi‐family buildings, this presentation will cover engineered wood product acceptance, testing requirements, lateral design, and proper detailing. Learning Objectives Testing requirements and acceptance of wood I‐joists and structural composite. Lumber (SCL) products; Dimension stability in regards to moisture content changes and the differences between solid wood products. Lateral design, including information on I‐joist diaphragm capacities and the detailing of rim board connections. Fire resistance design, including wood I‐joist assembly requirements and SCL char rate equivalency to solid wood. Course Video Speaker Bio Jeff Olson, P.E., P.Eng. Technical Services Manager – Boise Cascade, Engineered Wood Products Division Boise Cascade White City, OR Jeff is currently the Technical Services Manager for Boise Cascade, Engineered Wood Products division. He has over 30 years of experience in the design and testing of engineered wood products and is licensed as a Professional Engineer in several western Canadian provinces and U.S. states.

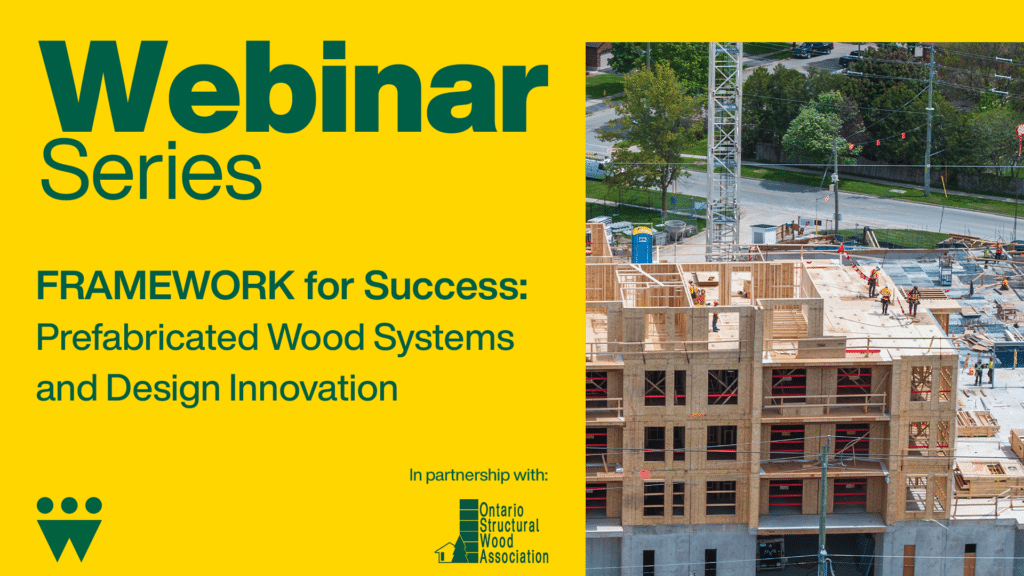

Efficient Tall Wall Framing using Engineered Wood Products

Course Overview This webinar will explore the basic design principles and best practices for efficient tall wall design using engineered wood products. Discussion will include material selection, design for climate conditions, and a complete design example using freely available software tools. Learning Objectives Understand the design principles and inputs required to size tall wall framing members. Recognize some of the pitfalls of inadequate tall wall design. Learn about easy-to-use tools and software available to simplify this process. Course Video Speaker Bio Steve McManus Senior Engineer Weyerhaeuser Steve McManus, a professional engineer based in Langley, BC, supports Weyerhaeuser’s Trus Joist® Engineered Lumber Products in residential and light commercial construction. He provides technical support, training, and field issue resolution for suppliers, architects, engineers, and building officials across Canada. Steve’s 27 years of experience in the forest industry includes structural design and engineering, forest management, and wood products manufacturing.