Wood Solutions Conference: Halifax 2025

Mark your calendars! WoodWorks Atlantic and the Canadian Wood Council are pleased to present the Wood Solutions Conference in Halifax this fall — and we want you there.

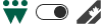

Wood Design & Building Magazine, vol 24, issue 97

In wood construction, success is rarely improvised. It’s the earned result of early design coordination, clearly communicated expectations, and a shared commitment to getting the details right—from design concept through to completion. Whether a project’s priority is accelerated construction timelines, lasting architectural impact, future disassembly and reuse, or all these things and more, the through line is thoughtful, deliberate planning. As a structural system, timber calls for a high degree of coordination—especially as its applications continue to evolve and expand. It rewards teams who design with intent: those who understand that every exposed surface carries architectural weight, that detecting clashes early in the design phase avoids costly rework during construction, and that planning for a building’s end-of-life is just as essential as designing its first impression. Society’s growing demand for low-carbon construction brings new urgency—and opportunity—to these conversations. As we continue to advance prefabricated, high-performance, and demountable wood building systems, the need for early alignment—between architect and engineer, builder and client—is not just integral to the success of individual projects, but to the advancement of the industry as a whole. This issue of Wood Design & Building leans into that reality. As construction methods evolve, we examine how clear communication and coordination don’t just mitigate risk—they drive better outcomes for the built environment. In a construction landscape that values speed, efficiency, and low-carbon outcomes, it’s advanced planning and clear communication that turn ambition into meaningful results. We’re not just building with wood. We’re building with purpose, intention, and care. And that process starts long before the first beam or panel is lifted into place.

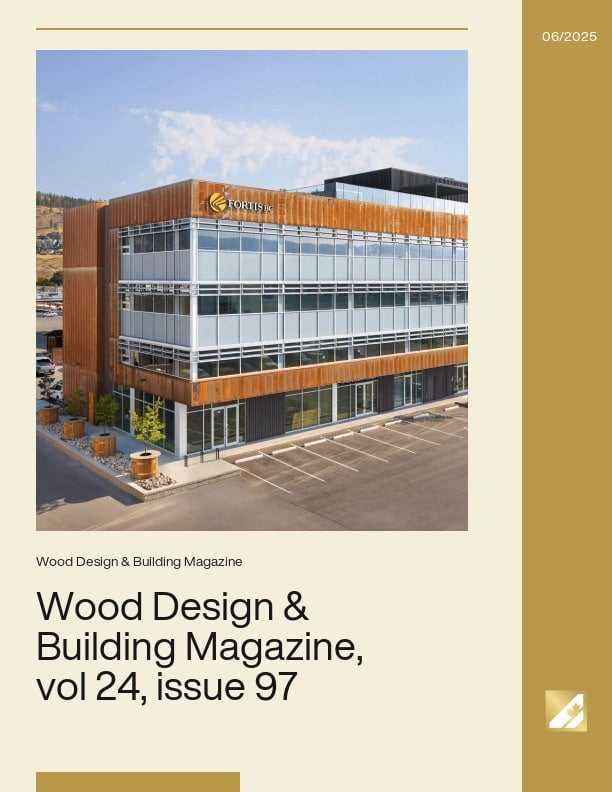

UNB Head Hall – Engineering Commons

The Engineering Complex at UNB is comprised of five buildings, all constructed at different times, and physically connected as one. The first building constructed in 1901, was the original Engineering Building, designed in the Romanesque Revival style, followed closely thereafter by the former Gymnasium, converted in 1944 to the Electrical Engineering Build-ing. In 1957, an expansion to the western side of the two original engineering buildings was made. Sir Edmund Head Hall, a five-storey, 13,600 sq.m (140,000 sf) addition was con-structed to the north of the previous mentioned buildings. Gillin Hall was added to the west side of Head Hall in 1989 and the Information Technology Centre was added to the south of Gillin Hall along Windsor Street in 2000. In April of 2017, UNB requested Murdock & Boyd Architects to come up with a design solution for a new prominent Main Entrance to the Head Hall Engineering Complex, one that celebrates the engineering programs that are delivered at this institution. The space is designed to allow for and promote the collaboration and interaction of students and faculty, provide for additional graduate study areas, larger crush space from the Dineen Auditorium and a space to exhibit and visually celebrate all the disciplines of the world renowned UNB Engineering programs and its graduates.

Webinar: Understanding Glulam: The structural and architectural capabilities of mass timber

Webinar: Building Code Updates for Tall Wood Construction in Canada

Brampton – Simpson Strong-Tie Workshop

This workshop covers wood construction connectors, design apps, mass timber connectors, mass timber fasteners, structural screws, and anchor systems, with demonstrations on hanger testing, fastener installation, and anchor installation and testing.

A Practical Path Forward for Offsite Manufacturing

This report serves as a practical guide for small to medium-sized enterprises, start-ups, and builders looking to transition into offsite construction. With a specific focus on prefabricated elements and modular systems, it offers actionable guidance for manufacturers considering process expansion or upgrades. Covering critical topics such as business planning, transformational change, financial efficiency, design for manufacturing and assembly (DfMA), and technology integration, the report emphasizes that success in offsite construction depends not only on technical capability, but also on strategic foresight and organizational readiness. Drawing on lessons from both successful and stalled ventures, the report identifies common pitfalls—including rushed implementation, cultural resistance, and premature technology investment—and outlines a disciplined, step-by-step approach to navigating them. Through key themes such as aligning prefabrication with business goals, managing operational change, optimizing financial strategies, and adopting technology judiciously, the report provides a roadmap for sustainable growth. Its insights advocate for a manufacturing mindset rooted in efficiency and adaptability, helping firms approach offsite construction with confidence, clarity, and resilience.

Mass Timber Construction Success Checklist

Mass timber construction offers speed, sustainability, and design flexibility – but it also requires a higher level of coordination than traditional structural systems. Its prefabricated components and tight tolerances call for early planning, clear communication, and a shared understanding across the project team. Ensuring that all partners – including those less familiar with timber construction – are aligned on these unique requirements helps avoid costly delays and, more importantly, positions the team to fully capitalize on the benefits mass timber has to offer.

Exploring the Role of Mass Timber – Industrial Buildings and Warehouse Construction

The emerging use of mass timber in industrial buildings presents promising opportunities that are shaping the future of construction in this sector. As a sustainable and economically competitive alternative, mass timber is redefining industrial construction, a field traditionally dominated by prefabricated steel. An analysis of two cutting-edge projects in Sudbury, Ontario, highlights key advantages, including cost competitiveness, reduced embodied carbon, and aesthetic appeal. The insights from these two projects present stakeholders with helpful considerations and valuable strategies for integrating mass timber into future developments.

2025 Wood Design & Building Awards Call for Submissions Now Open

OTTAWA, ON, 23 APR 2025 – The Canadian Wood Council is accepting submissions for the 2025 Wood Design & Building Awards. Now in its 41st year, this annual program invites architects, designers, and project teams from across North America and around the world to submit their most inspiring wood projects for consideration. “At its core, this program is a celebration of architectural excellence,” says Martin Richard, VP Market Development & Communications at the Canadian Wood Council. “Each year, we’re inspired by the many ways designers harness wood’s versatile beauty—from bold, expressive forms to quietly transformative spaces.” Over the decades, we’ve seen the creativity and talent of hundreds of project teams bring important changes to the built environment—elevating wood from a niche material to a sustainable, mainstream design ambition. While the awards program has always shone a light on architectural excellence in wood, winning projects in recent years also frequently demonstrate innovation, technical achievement, and a strong commitment to sustainability. Submissions will be reviewed by a distinguished jury of Canadian and American architects. Projects will be evaluated based on creativity, design excellence, and the innovative and appropriate use of wood to achieve project objectives. Award categories for 2025 include: The program also includes several specialty awards: Winners will receive a custom wood trophy and be recognized through a media announcement, social media, a feature profile on the Wood Innovation Network, and editorial coverage in Wood Design & Building Magazine (digital edition). Key DatesEarly Bird Deadline: May 31, 2025Final Submission Deadline: June 27, 2025 For more information and to submit your project, please visit: https://cwc.ca/wood-design-and-building-awards/

Wood Decay and Repair

LEAKY BUILDINGS AND DECAYING WOOD – WHAT’S HAPPENING? The news across North America seems to frequently contain stories about serious moisture failures in wood-frame buildings. Whether it’s Vancouver’s “leaky condo crisis” or the “EIFS disaster” in North Carolina, homeowners are struggling with wood decay wherever the other components of the building’s walls and roof aren’t properly protecting the wood structure from excessive moisture. Interestingly, leaks are also getting attention in steel and concrete high-rises, causing rust in steel studs and fasteners and degradation of gypsum wallboard. Why are we suddenly finding so many failures in buildings, including in our tried-and-true wood construction? This is a frustrating problem for everyone in the building industry, because there are no easy answers. It’s convenient to blame unskilled or unethical practitioners in the building industry. Other occasional targets for blame include municipalities for developing zoning ordinances that conflict with performance issues; energy efficiency codes for making our building envelopes tighter; new and complicated materials in our building envelopes; the building occupants for not practising proper maintenance; or the wood, which some seem to feel has declined in quality. The bottom line: many people have opinions, but so far there is little firm technical data to answer these questions. Please see our Links page for some of the research institutions working in this area. Buildings have probably always leaked, although it is only recently that moisture seems to be a problem. Some believe that the difference is that today’s buildings are less tolerant of those leaks; that perhaps the older buildings were able to dry out. Another theory is that today’s leaky buildings leak more than in the past, due to design errors, sloppy construction, lack of overhangs, etc. Thankfully, many people working in the building industry have turned their attention towards better design and construction practice for moisture control. A number of “best practice guides” are listed in our Links section. HOW CAN I TELL IF WOOD IS DECAYED? If wood is badly decayed, this will be quite obvious. The wood will be soft and perhaps even be breakable by hand. Decayed wood breaks with a carrot-like snap versus the splintering of sound wood. Use the pick test to be sure. MY WOOD IS STAINED – IS IT DECAY? Probably not, if this is new lumber. There are many harmless sources of wood stains, including dirt, iron filings, or staining fungi that merely colour the wood without damaging it. Please see the fact sheet “Discolourations on wood products: Causes and Implications” for a thorough explanation including photos. If the discoloured wood is found in a leaky building under repair and may have been wet, perform the pick test to see if it is rotted – see our page on Assessing decay. I HAVE DECAYED WOOD – WHAT SHOULD I DO? Remove all decayed wood and additionally remove another two feet of sound wood all around the decayed section. Any sound wood that is left in place when decayed wood around it has been removed should be field treated with a penetrating preservative. Also field treat any wood that may continue to get wet after repairs. We recommend preservatives containing a diffusible low-toxicity fungicide such as sodium borate, and low-toxicity formulating agents which assist in penetrating dry wood, such as propylene glycol. By the time the cladding has been removed, the structure has been inspected and the decayed wood has been removed, the wood left in place will likely have dried too much for effective use of formulations without a penetration aid. Under conditions of high relative humidity, the propylene glycol may cause a short term increase in the moisture content at the wood surface. For more information, please see our page on Assessing decay. IS KILN-DRIED LUMBER MORE RESISTANT TO DECAY THAN GREEN OR AIR-DRIED LUMBER? One advantage of kiln-dried lumber is that any live fungi present in the green lumber will have been killed by the heat of the kiln; in other words, KD lumber is sterile after leaving the kiln. However, if it gets sufficiently wet afterwards, then it is at the same risk of decay as any other wood. ARE COMPOSITE WOOD PRODUCTS MORE RESISTANT TO DECAY THAN SOLID LUMBER? No. Composite products (glulam, OSB, laminated veneer lumber, etc.) have the same resistance to decay as the wood from which they were made. The adhesives used in composites do not affect decay resistance. DO WE HAVE TERMITES IN CANADA? Yes, in a few limited areas across the country and to a greater extent around Toronto, termite species causing damage to buildings are present. Although termites are a significant problem in parts of southern Ontario, overall they are only a mild concern in this country. They prefer warmer conditions and are a far greater problem in parts of the United States. In Canada we do not have the voracious Formosan subterranean termite causing so much damage in the southeastern US. WHAT IS DRY ROT? Contrary to popular usage, dry rot does not mean rot that can happen in dry wood, or wood that has rotted and dried out. Dry rot is a specific kind of fungus, although the term is very commonly misused to describe all wood rot. This is unfortunate, because it disassociates rot from moisture. Wood rot always requires moisture, and the key to wood durability is the control of moisture. Wood that rotted long ago and is now dry was moist at the time of the rot. The true dry rot fungus has the ability to tap into a water source and conduct water to what would otherwise be dry wood. However, it has to wet the wood before it can attack the wood. The true dry rot fungus is more likely to be found in buildings that contain brick or stone than in all-wood buildings. HOW FAST DOES WOOD DECAY? It’s impossible to say; there are so many variables that influence the process. In a laboratory, under ideal conditions for decay fungi, wood can rot quite quickly.

The Exchange

ARCHITECT: Faction Architecture Inc. STRUCTURAL ENGINEER: RJC Engineers DEVELOPER: Faction Projects Inc. CONSTRUCTION MANAGER: Faction Construction BUILDING CODE CONSULTANT: GHL Consultants Ltd. PHOTOS: Courtesy of naturally:wood In Kelowna, British Columbia’s evolving industrial north end, The Exchange stands as a forward-thinking demonstration of what’s possible when architectural ambition meets technical precision. Designed and developed by Faction Architecture and Faction Projects, the building blends mass timber with conventional materials in a hybrid system that highlights both structural performance and environmental responsibility. At the heart of the structural system is nail-laminated timber (NLT), used for both floor and roof assemblies. NLT is a mass timber product formed by mechanically fastening dimensional lumber together to create solid panels—an approach well-suited to exposed timber applications that value durability, texture, and straightforward fabrication. For this project, the team fabricated the panels in-house using locally sourced materials and trades. While this gave them greater control over cost and scheduling, it also introduced design and compliance challenges. The team opted for a fluted NLT profile to enhance visual appeal and improve acoustic performance. Because the panel design differed from prescriptive norms, it required approval as an alternative solution under the BC Building Code. Extensive analysis was conducted to demonstrate compliance with fire-resistance, vibration, and load-bearing requirements. Informed by existing NLT fire test data, the design team minimized voids between laminations to enhance charring behaviour and performed physical load testing at Okanagan College to confirm strength and stiffness performance. Complementing the NLT panels is a glulam post-and-beam system that forms the substructure, supported by concrete elevator and stair cores. Together, these elements support a program that includes retail and light industrial space at grade, with two to three storeys of open-plan office space above. A rooftop patio offers sweeping views, reinforcing the project’s appeal to creative businesses and environmentally conscious tenants. The Exchange also showcases a thoughtful approach to the building envelope, a key factor in achieving Step 3 of the BC Energy Step Code—the highest step currently applicable to non-residential buildings in the region. The high-performance envelope includes a combination of weathering steel and corrugated metal cladding, high-performance glass windows, semi-rigid exterior insulation, breathable weather barrier, plywood sheathing, lumber studs, batt insulation, gypsum board and a polyethylene vapour barrier. The light-frame wood walls contribute to envelope performance in two important ways: 1) wood has lower thermal conductivity than other materials, so thermal bridging is dramatically reduced, and 2) the stud wall configuration allowed for thicker insulation in the cavities between studs. This integrated approach—combining exposed timber construction, envelope efficiency, and locally supported fabrication—enabled the project team to deliver a space that performs as well technically as it does aesthetically. And with over 90% of the leasable area spoken for at completion, it’s clear that tenants are responding to both the look and the logic of the building. The Exchange sets a precedent for accessible mass timber construction in smaller markets, particularly in contexts where a streamlined fabrication process and strong design-control loop can help close the gap between sustainable ambition and budgetary constraints. As Faction Projects continues work on the remaining phases of the development, The Exchange stands as both a technical prototype and a commercial success—proof that high-performance, low-carbon construction can be as practical as it is inspiring.