Ottawa, Ontario – October 16, 2025 — The Canadian Wood Council (CWC) is pleased to welcome Rothoblaas Canada as a new national partner of its WoodWorks program. This collaboration aligns two organizations committed to advancing wood construction across Canada through education, technical support, and strategic market development.

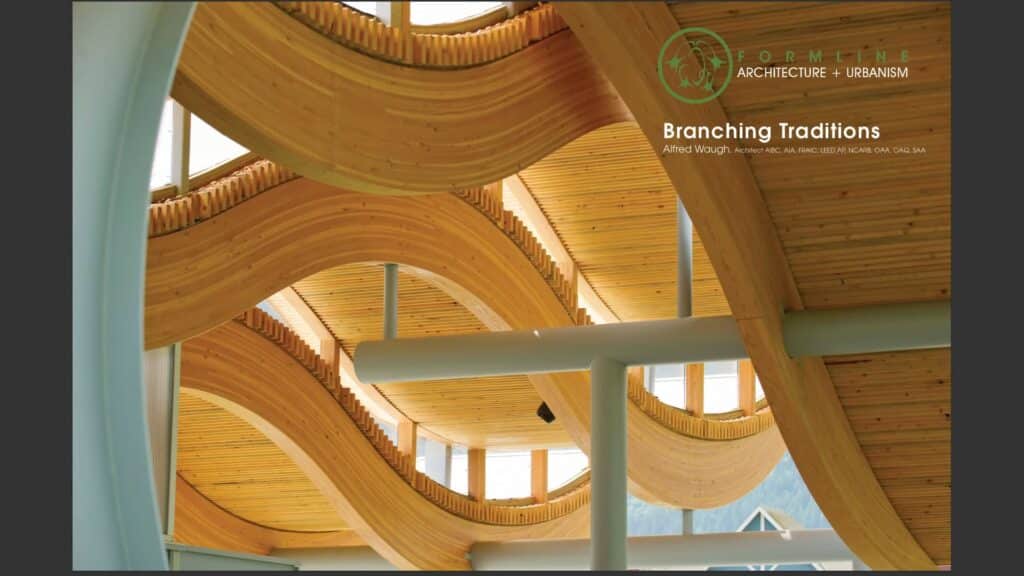

As demand for high-performance, low-carbon buildings drives greater adoption of mass timber and other engineered wood systems, this partnership will strengthen the technical ecosystem supporting Canada’s construction industry. Leveraging Rothoblaas’s international leadership in structural connection technologies, envelope systems, and on-site safety solutions alongside WoodWorks’ national expertise in education, technical support, and market development, the collaboration will help advance best practices in timber design and construction. Together, the organizations will facilitate knowledge transfer and design innovation to support the integration of wood as a mainstream material in Canadian building projects.

“For more than 20 years, WoodWorks has been delivering technical expertise and support to the professionals advancing wood construction across Canada. Partnering with this respected network allows Rothoblaas Canada to share our global engineering experience and help drive innovation in connection systems, building envelope performance, and safe, efficient timber assembly,” says François-Laurent Chabot, General Manager & Region Sales Manager for Rothoblaas Canada.

“WoodWorks is proud to collaborate with Rothoblaas Canada to help build industry knowledge and acceptance of modern timber connection systems and other assembly solutions,” says Rick Jeffery, President and CEO of the Canadian Wood Council. “This partnership integrates Rothoblaas Canada’s expertise in engineered connectors and building envelope technologies with WoodWorks’ national platform for education and sector advancement—supporting a more seamless, performance-based approach to wood construction.”

Through shared outreach, resource development, and technical education across the country, this national partnership aims to equip architects, builders, and developers with the knowledge they need to confidently design and build with wood. Broader adoption of wood solutions can play a pivotal role in meeting national housing and infrastructure goals, while contributing to Canada’s climate objectives and the transition to a low-carbon economy.

About the Canadian Wood Council

The Canadian Wood Council (CWC) is Canada’s unifying voice for the wood products industry. As a national federation of associations, our members represent hundreds of manufacturers across the country. Our mission is to support our members by accelerating market demand for wood products and championing responsible leadership through excellence in codes, standards, and regulations. We also deliver technical support and knowledge transfer for the construction sector through our market leading WoodWorks program.

About the National WoodWorks Program

The Canadian Wood Council’s WoodWorks Program a national outreach initiative dedicated to advancing the use of wood in construction by providing educational opportunities and direct technical support. The program helps architects, engineers, developers and other industry professionals expand their capacity for wood design and construction, contributing to a more sustainable built environment.

About Rothoblaas Canada

Rothoblaas Canada is a leading provider of innovative solutions for mass timber and wood construction, offering a comprehensive range of structural fasteners, connection systems, membranes, and safety products. As part of the global Rothoblaas group, the Canadian division supports architects, engineers, and builders with technical expertise and code-compliant solutions tailored to local needs. Through research, education, and collaboration, Rothoblaas Canada advances high-performance, sustainable construction and helps drive the growth of Canada’s wood building industry.