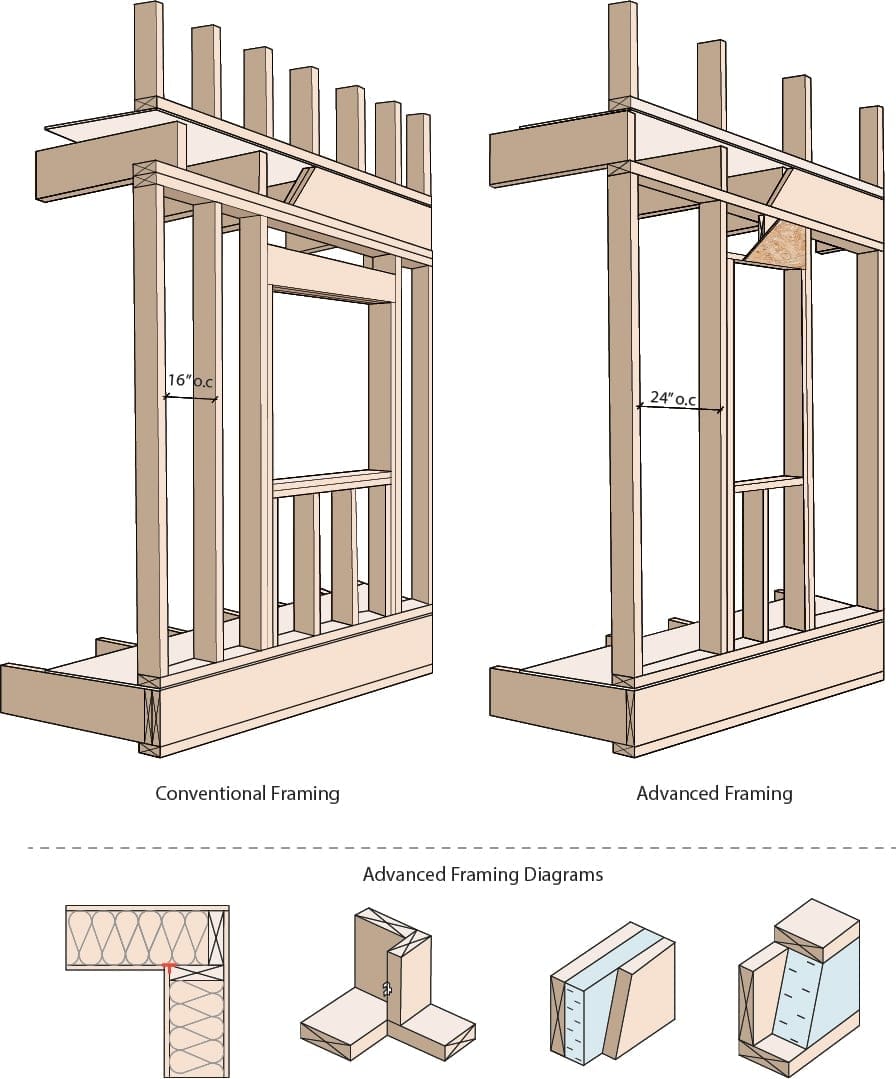

“Advanced Framing” in the EffectiveR Calculator: Advanced framing is a construction framing system designed to reduce lumber usage and increase energy efficiency. Advanced framing is resource efficient and offers more space for insulation while reducing heat loss through conductive framing members. Conventional framing, the industry standard for framing residential construction, typically consists of 2×4 (38 x 89mm) or 2×6 (38 x 140mm) wood framing spaced 16 inches (406mm) on center, double top plates, three-stud corners, multiple jack studs, double or triple headers, cripple studs, and other members that are often redundant. Advanced framing reduces the structural redundancies inherent in conventional framing by placing framing members only where they are needed. The most commonly adopted advanced framing technique is 2×6 (38 x 140mm) wood framing spaced 24 inches (610mm) on center. Other commonly used techniques include single top plates, two-stud corners, single headers or integrated rim headers, minimal use of jack studs and cripples, and the elimination of redundant studs and unnecessary blocking and bridging. Although some advanced framing techniques can be adopted independently, the greatest savings- in both cost of construction and energy- will be realized when the system is applied holistically. The National Building Code Note A-9.36.2.4.(1) describes advanced framing, and provides framing and cavity percentages in Table A-9.36.2.4.(1)-A. The calculator uses these percentages, which equate to a 4% reduction in framing for stud spacing of 16″ (406mm), 19.2″ (488mm), and 24″ o.c. (610mm).

|

Details addressed in this section may relate to:

|

| Materials Serving More Than One Function Modern building components will, in many instances, serve more than one function within the wall assembly. Polyethylene is the clearest example of a component that acts both as a vapour barrier and when it is properly sealed also as an air barrier. New products that have been designed and tested can serve multiple functions. For instance, some exterior insulating sheathings that are properly sealed can act as insulation but also as air barriers and weather barriers or in the language used by the building code as sheathing membranes that are part of the wall’s second plane of protection. In some situations, liquid applied water resistive barriers can act as sheathing membranes. In all cases, you should look for an approval by the Canadian Construction Materials Centre or an approval using Division A of the Building Code in force in your location. When in doubt, check with your local building department. |

| Additional Sources of information There are unlimited resources at the professional’s finger tips when it comes to sourcing product and assembly information. However, it can often be a challenge to quickly locate reliable, relevant building science and assembly information as it pertains to each individual Canadian Climate zone. In this section the Designer/Builder Professional can access everything from construction details, scopes of work, relevant and current research and links to approved assembly materials and methods. |

CWC MEGA MENU

About Us

Menu

Why build with wood?

Menu

How to build with wood

Menu

Need help building with wood?

Menu

Be inspired to build with wood

Menu

CWC MEGA MENU

About Us

Menu

Why build with wood

Menu

How to build with wood

Menu

Need help building with wood?

Menu

Be inspired to build with wood

Menu